In an era where environmental concerns are at the forefront of design and construction industries, staircase manufacturing is not left behind. Sustainable practices are increasingly becoming a priority, as both consumers and manufacturers seek to minimize environmental footprints while delivering high-quality, durable products. This article explores how sustainability is being integrated into staircase manufacturing, marking a shift towards more eco-conscious production methods.

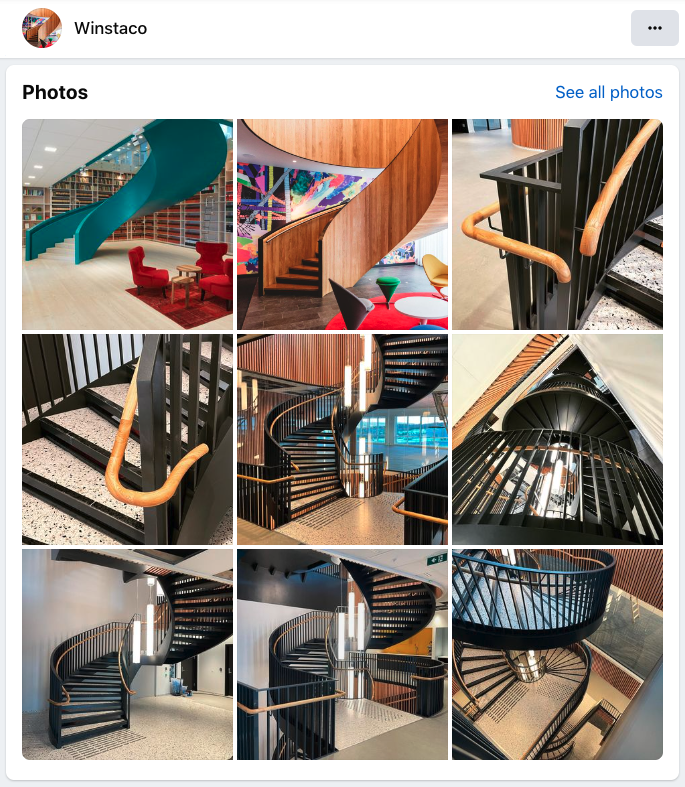

Photo credit: Dan Freeman

The Drive for Sustainability

The push towards sustainable manufacturing arises from a collective awareness of the environmental impacts associated with traditional construction materials and processes. In staircase manufacturing, this has translated into an exploration of eco-friendly materials, energy-efficient production methods, and recycling and reuse strategies that contribute to a more sustainable lifecycle for staircase products.

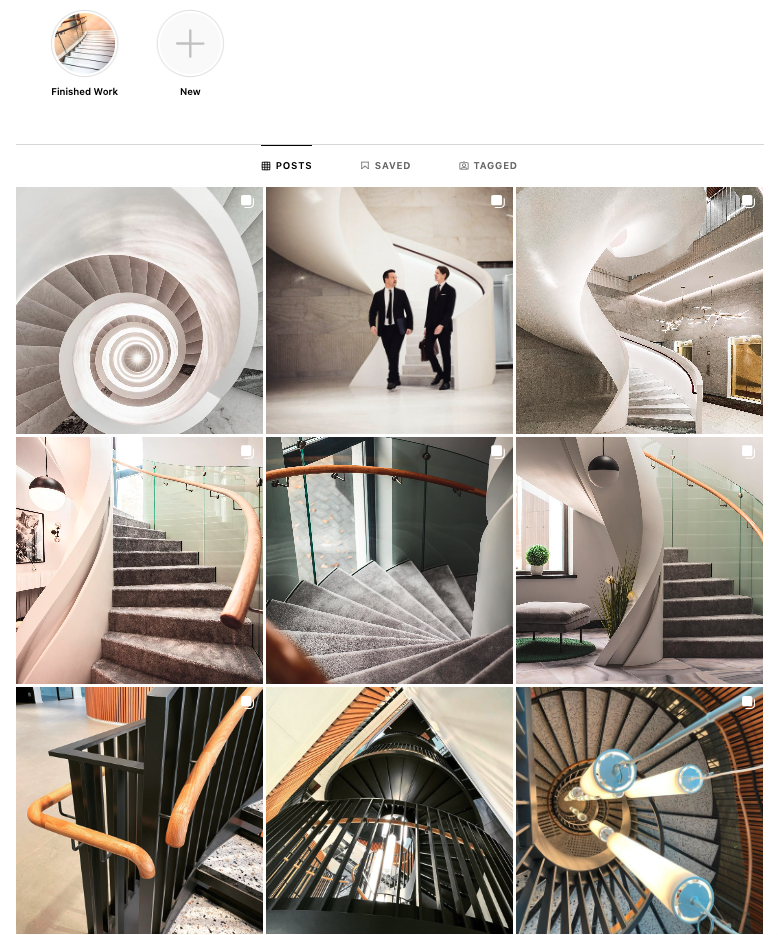

Eco-friendly Materials

Choosing the right materials is crucial in sustainable staircase manufacturing. Options like reclaimed wood, recycled metal, and sustainable composites are gaining popularity. These materials not only reduce the depletion of natural resources but also offer unique aesthetic qualities that enhance the design of staircases.

Reducing Carbon Footprint

Manufacturers are adopting practices that reduce energy consumption and carbon emissions. This includes optimizing production processes, utilizing renewable energy sources, and minimizing waste through precise planning and cutting-edge technology. Such initiatives not only contribute to environmental conservation but also lead to cost savings and efficiency improvements.

Lifecycle Consideration

A sustainable approach to staircase manufacturing involves considering the entire lifecycle of the product. This means designing for durability, ease of maintenance, and eventual recyclability. By creating staircases that last longer and can be easily repurposed or recycled at the end of their life, manufacturers are contributing to a circular economy that values resourcefulness and sustainability.

The Role of Innovation

Innovation plays a key role in sustainable staircase manufacturing. From utilizing biodegradable resins in composite materials to implementing advanced manufacturing techniques that reduce waste, the industry is constantly seeking new ways to improve sustainability. These innovations not only make staircase manufacturing greener but also open up new possibilities in design and functionality.

Conclusion

Sustainable practices in staircase manufacturing represent a significant shift towards more environmentally responsible construction. By focusing on eco-friendly materials, reducing carbon footprints, considering product lifecycles, and embracing innovation, manufacturers are setting a new standard in the industry. This not only benefits the planet but also offers homeowners and businesses staircases that are beautiful, durable, and environmentally friendly.