As we step into the heart of summer, the world of interior design is embracing a fresh wave of inspiration. In 2025, it’s all about natural elements, light-filled spaces, and statement features that blend luxury with warmth.

1. Earth Tones & Natural Textures

Interior palettes are shifting toward soft beiges, warm terracottas, sandy whites, and calming greens. Paired with materials like linen, oak, and stone, this summer’s spaces are designed to feel earthy and grounded, yet modern and elegant.

2. Open Spaces & Architectural Flow

Open-plan living continues to dominate, with more attention now being paid to how one space flows into another. And right at the heart of that flow—both physically and visually—is often the staircase.

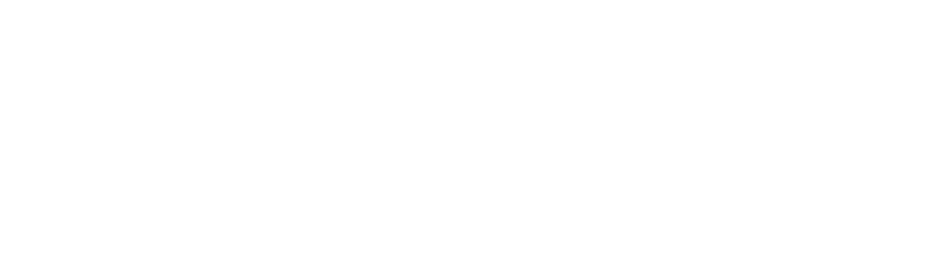

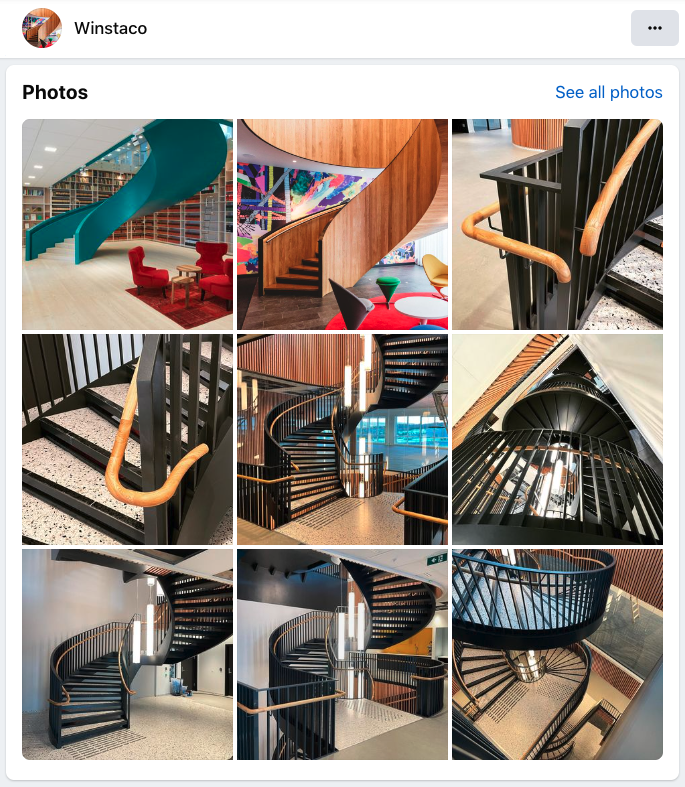

3. Staircases as Statement Pieces

No longer just functional, staircases are becoming the centerpiece of contemporary homes. This summer, we’re seeing increased demand for staircases that act as a sculptural element—minimalist floating steps, curved wood designs, or elegant steel structures that catch the eye the moment you enter.

At Winstaco, we believe a staircase is not just a way to move between floors—it's a way to express style, personality, and craftsmanship. Whether you prefer something timeless or trend-forward, our team helps bring your staircase vision to life, tailored to your home’s design.

4. Light as a Design Element

Natural light is a must this summer, and designers are finding clever ways to let the sun in—glass walls, skylights, and strategically placed stairwells that help light flow from one level to the next. Our custom staircase solutions often integrate with these design elements, making the most of both form and function.

5. Organic Shapes & Softer Lines

Curved furniture, arched doorways, and spiral staircases are gaining popularity, offering a softer, more welcoming look. These organic forms pair beautifully with nature-inspired interiors, creating a sense of calm and fluidity in the home.

Ready to Elevate Your Space?

Whether you're renovating or building new, this summer is the perfect time to create a home that feels fresh, open, and inspired. If you're dreaming of a luxurious, handcrafted staircase that matches the latest interior trends—or even sets new ones—Winstaco is here to make it happen.